Strength is a crucial mechanical property used to evaluate materials’ performance and durability. Yield strength is one of the most important properties used in material testing. It is the stress under which a material starts to deform permanently. Yield strength is determined by performing a tensile test, which measures the amount of stress required to deform the material.

What is Offset Yield Strength – An Analysis

Offset yield strength is a variant of yield strength commonly used in the material testing industry. This strength property is the stress required to produce a specified amount of plastic deformation (usually 0.2%) in a material. In other words, it is the stress at which a material exhibits a permanent deformation of 0.2% offset from the initial gauge length. The 0.2 offset yield strength is expressed in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa).

The offset yield strength is a critical parameter in designing and testing materials for various applications, such as aerospace, automotive, and structural engineering. The 0.2% offset yield strength is an essential mechanical property of metals, plastics, and other materials, as it determines their strength and ability to withstand stress.

The 0.2 offset yield strength is an important indicator of a material’s strength under stress, reflecting the point at which the material begins to yield or deform plastically. Materials with higher offset yield strengths can withstand higher stress loads before they deform permanently. Therefore, materials with higher offset yield strengths are more suitable for applications that require high strength and durability, such as structural engineering, aerospace, and automotive applications.

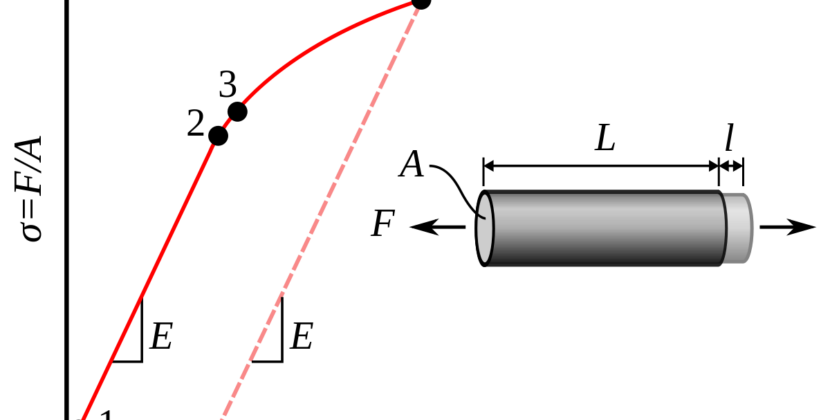

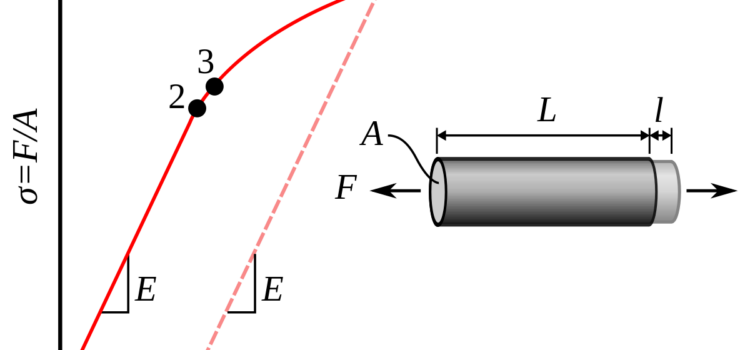

The offset yield strength is usually determined using a tensile test, which involves pulling a specimen of the material until it breaks. The material’s deformation is recorded during the test, and stress-strain curves are plotted. The offset yield strength is then calculated by drawing a line parallel to the elastic region of the stress-strain curve, offset by 0.2% from the original gauge length. The point where the offset line intersects with the stress-strain curve is the 0.2 offset yield strength.

The 0.2 offset yield strength is often used in material specifications and standards, such as ASTM and ISO, to ensure consistency and quality control in materials used for various applications. These standards specify the minimum and maximum 0.2 offset yield strength for different materials, which must be met or exceeded to ensure that the material meets the required strength and durability criteria.

Conclusion

Simply put, the 0.2 offset yield strength is an essential mechanical property used to evaluate the strength and durability of materials. It is determined by performing a tensile test and measuring the stress required to produce a specified amount of plastic deformation. The 0.2 offset yield strength is an important parameter in designing and testing materials for various applications, such as aerospace, automotive, and structural engineering. Therefore, it is crucial to understand and control the 0.2 offset yield strength of materials to ensure their reliability and safety in different applications.